MORE PERFORMANCE WITH IoT 4ECO SMART

MANAGEMENT, MONITORING AND CONTROL OF AIR FILTRATION AND PURIFICATION SYSTEMS FROM DUST FROM INDUSTRIAL AND ARTISAN PROCESSES.

Why invest in monitoring the performance of plants and machines?

Being able to keep an industrial site under control does not only mean knowing what is happening on each machine or line at all times, but also allows you to use the data to improve maintenance processes and increase their efficiency. This means eliminating all those wastes that in the past could not be avoided, managing targeted maintenance interventions, avoiding both unnecessary replacements and machine downtime. Through the combination of data obtained in real time through IoT 4 ECO SMART, predictive maintenance analyzes the state of the plant during its operation, to reduce the probability of unexpected machine failure.

Main features of IoT 4 ECO SMART

- Access from PC, SMARTPHONE AND TABLET H24

- Multi-user platform with different levels of access and operation

- The IoT 4 ECO SMART system consists of an electronic device that can be installed inside the electrical panel of the filtering system, or in a separate box, applied directly to the filter. It collects data from the various sensors and uses their values to make the necessary adjustments.

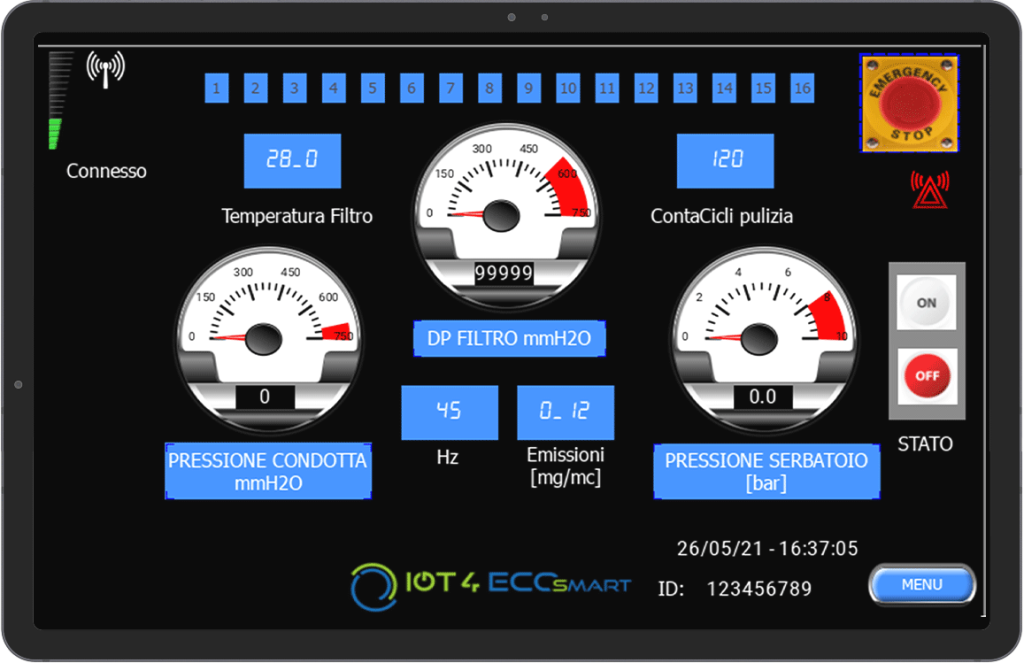

- The TOUCH SCREEN on the electrical panel allows operators to view the operating status of the system.

- The "alarm history" function allows you to view the alarms that have occurred in the past on the system. It is possible to acquire with graphs, the values detected by probes or meters, and to display them on the screen or export the data in .csv format to consult or analyze them on a PC in table format.

IOT4-EcoSmart is a tool designed and studied ad-hoc for the figure of the Energy Manager who supervises the effectiveness and energy efficiency of the systems.

What are the functions of the IoT 4 ECO SMART integrated system?

Through the real-time remote control of the system status it is possible to:

- view the status of the components of the filtration system such as motors, digital pressure switches, filter cleaning, flow switches, level sensors, rotary valves, augers, Tribo probes, solenoid valves, heaters ...

- monitor in real time the emissions into the atmosphere, the temperature of the filter, the number of cleaning cycles performed, the consumption of compressed air; keep under control the main operating parameters of the filter such as the pressure in the suction duct or the Δp of the filter.

- View the status of alarms in progress

- View the status of scheduled maintenance

Scheduled maintenance is a fundamental operation to keep the filtering system in efficiency. It is therefore essential to send alerts by IoT 4 ECO SMART regarding the expiration of the various maintenance operations, with the indication of the code of the component to be replaced to facilitate, improve and speed up maintenance operations.

System configuration: on which parameters can you act?

- CLEANING: customization of the number of cleaning valves and opening times during firing, as well as the optimal minimum and maximum working pressures.

- INVERTER: setting the minimum and maximum limits to which the adjustment action of the suction motor must be subject

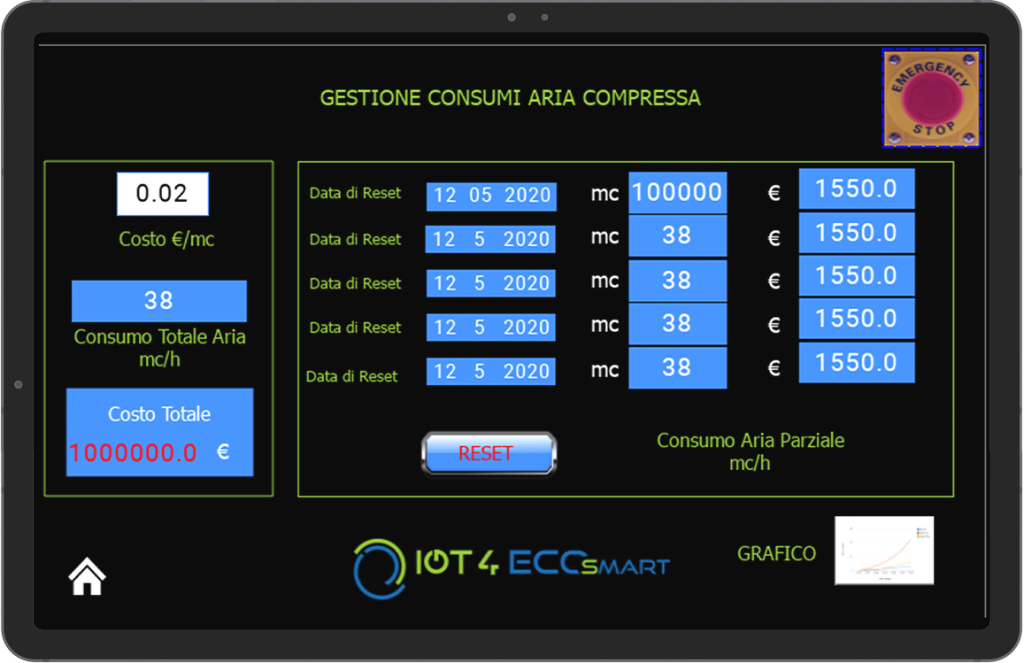

- FLOW METER: evaluation of the consumption of compressed air used for cleaning the filter elements to optimize costs in relation to yield.

- VALVE SHOOTING SEQUENCE: customization of the firing sequence of the various valves in order to optimize and improve the cleaning system.

- DEDUSTING INTERVAL: The correct setting of the pressure Δp is essential for starting the cleaning cycle and the one at which the cycle must end.

- PRESSURE STABILIZER: Setting the pressure stabilizer allows you to correctly adjust the suction fan, so that it maintains a constant suction flow.

- Tribo Probe Parameterization The Triboelectric probe detects the quantity of dust particles present in the ejection duct into the atmosphere and is an indication of the efficiency of the filtration process.

- Rotary valve parameterization. It allows to discharge the dusty residues collected in the filtering section during the cleaning of the system in the special container for the collection of filtration materials.

CONTACT US FOR MORE INFORMATION