ELECTRICAL PANELS AND INDUSTRIAL INSTALLATIONS

A complete service for electrical panels and industrial automation systems

Control production, access remotely, improve efficiency, reduce management and energy costs, receive alarm notifications, schedule maintenance, integrate with corporate IT.

01. Why invest in plant and machine monitoring?

Being able to monitor an industrial site not only means knowing what is happening on each machine or line at any time, but also allows you to use the data to improve maintenance processes and increase efficiency. This means eliminating all those wastes that could not be avoided in the past. The latest technologies in this sector make it possible to manage targeted maintenance interventions, avoiding both unnecessary replacements and machine downtime. The costs saved with these types of systems are much greater than you can imagine and consequently you have a return on investment in a short time. Our IOT 4 ECO SMART system is based precisely on these technologies and offers a 360-degree service for all types of needs. The IOT 4 ECO SMART supervisory system is a powerful IT platform designed to improve control, optimize efficiency and reduce costs of a production line. The purpose of IOT 4 ECO SMART is to create a network that allows communication between field devices and remote controllers. Many services are also made available to the user, designed to control, analyze and trace production; the powerful and intuitive interface can be accessed from any remote desktop or mobile device with an internet connection. Data collection is carried out via a VPN (Virtual Private Network) connection by connecting the field devices to the internet. This connection can be made via a wired network, wifi or 3G. The user can access the supervision via a web browser, desktop and mobile devices are supported. A secure internet connection is used for this connection. IOT 4 ECO SMART makes available to the user both the data collected from the field and those subsequently processed by the tools of the platform itself.

02. Maximum remote connectivity

Compared to traditional supervision, IOT 4 ECO SAMRT has significant advantages in terms of remote connectivity; it is possible to access the supervision from different workstations such as PCs, smartphones and tablets. User management allows the system administrator to define the different levels of access and operation. Multi-user connectivity also allows the use of supervision simultaneously by multiple operators in asynchronous mode.

CHECK

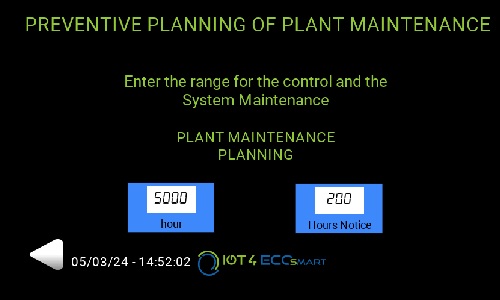

The IOT 4 ECO SMART platform allows the user to carry out a remote control in real time on the status of the system. In particular, it is possible to: View the status of utilities such as motors, digital pressure switches, filter cleaning control, flow switches, level sensors, rotary valves, augers, Tribo check probes, solenoid valves, heaters, etc. (on, off, manual or automatic). Read physical quantities such as temperatures, levels, speeds, etc. Modify the status of the users or the control adjustment set point, if allowed by the credentials assigned to the user who logs in. View the status of ongoing alarms. View the status of scheduled maintenance.

MOBILE CONNECTIVITY

Thanks to the mobile function, it is possible to connect to the system from smartphone and tablet mobile devices. The user has access to the supervision data in real time, and has the possibility to intervene by making changes from anywhere, if allowed by the assigned credentials.

ALARM HISTORY

The alarm history function allows you to view the alarms that have occurred in the past on the system. It is possible to carry out a search based on a time period or on the type of alarm. The database provides the user with the date and time of alarm intervention, acquisition and reset by the operator.

EMAIL NOTIFICATIONS

It is possible to receive e-mails and text messages in real time for the notification of conditions related to the production lines or production progress states, for example:

- Alarm or pre-alarm status.

- State of anomaly on production parameters such as cycle times, speeds, temperatures

- Component change request

- Operator intervention request

Notifications are scheduled in a totally "custom" way based on the Customer's requests. Different kinds of sending logics can be configured:

- With priority based on the type of signal.

SECTORS OF APPLICATIONS

Air filtration and suction systems. Heating, air conditioning, air treatment.